What is tPB?

A study published in Science Advances reports[1] a brand-new material called transparent paperboard (tPB). Made entirely from pure cellulose, it solves the century-old problem of opaque paperboard and sets a new bar for sustainability: it can be fully recycled in a closed loop and biodegrades across the entire ocean—from shallow waters to the deep sea.

Using a proprietary lithium bromide aqueous treatment, researchers have cured cellulose hydrogels into a range of practical shapes—from drinking straws to cups. Tests show that the tPB material matches plastic in everyday performance and can fully biodegrade within 12 months even in deep-sea conditions. With a plant-based resin coating, its leak resistance surpasses that of conventional paper cups.

1. Inspiration & Breakthrough: When Paperboard Becomes “Transparent”

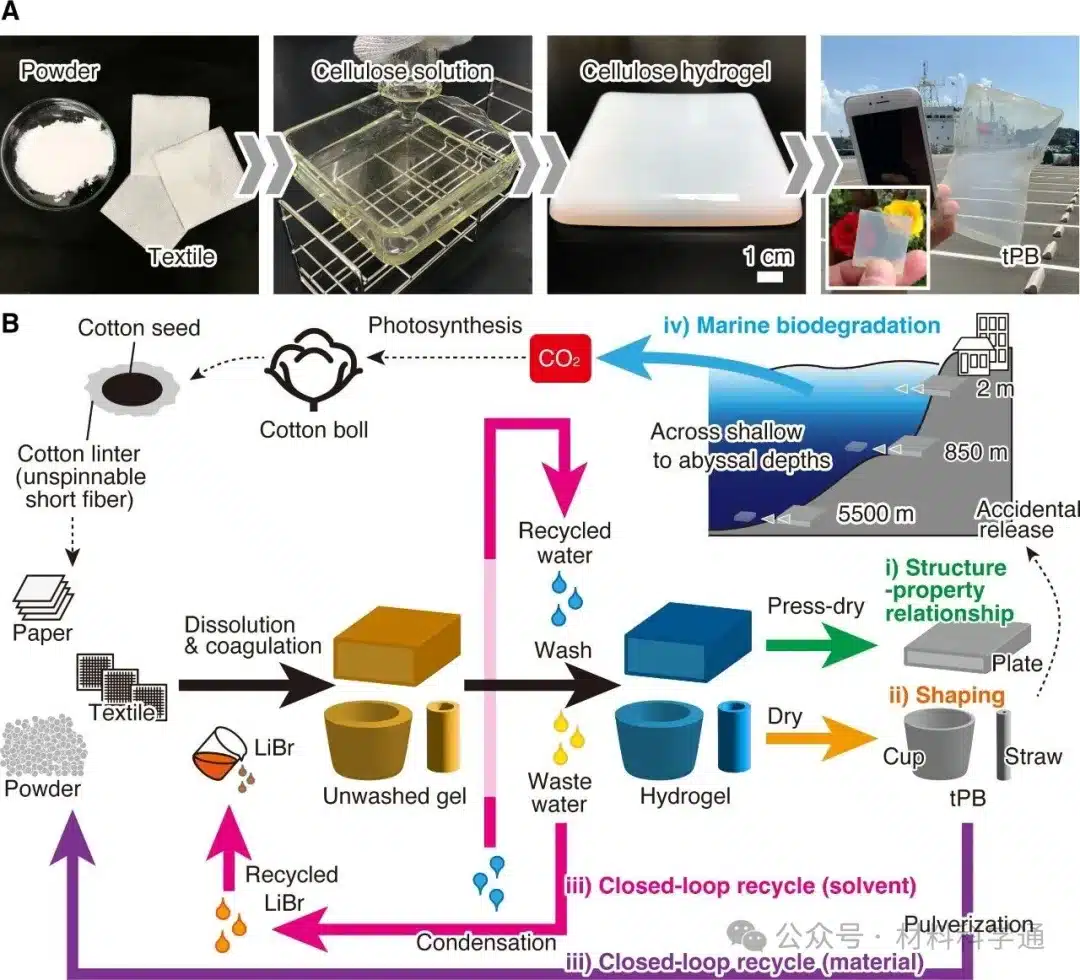

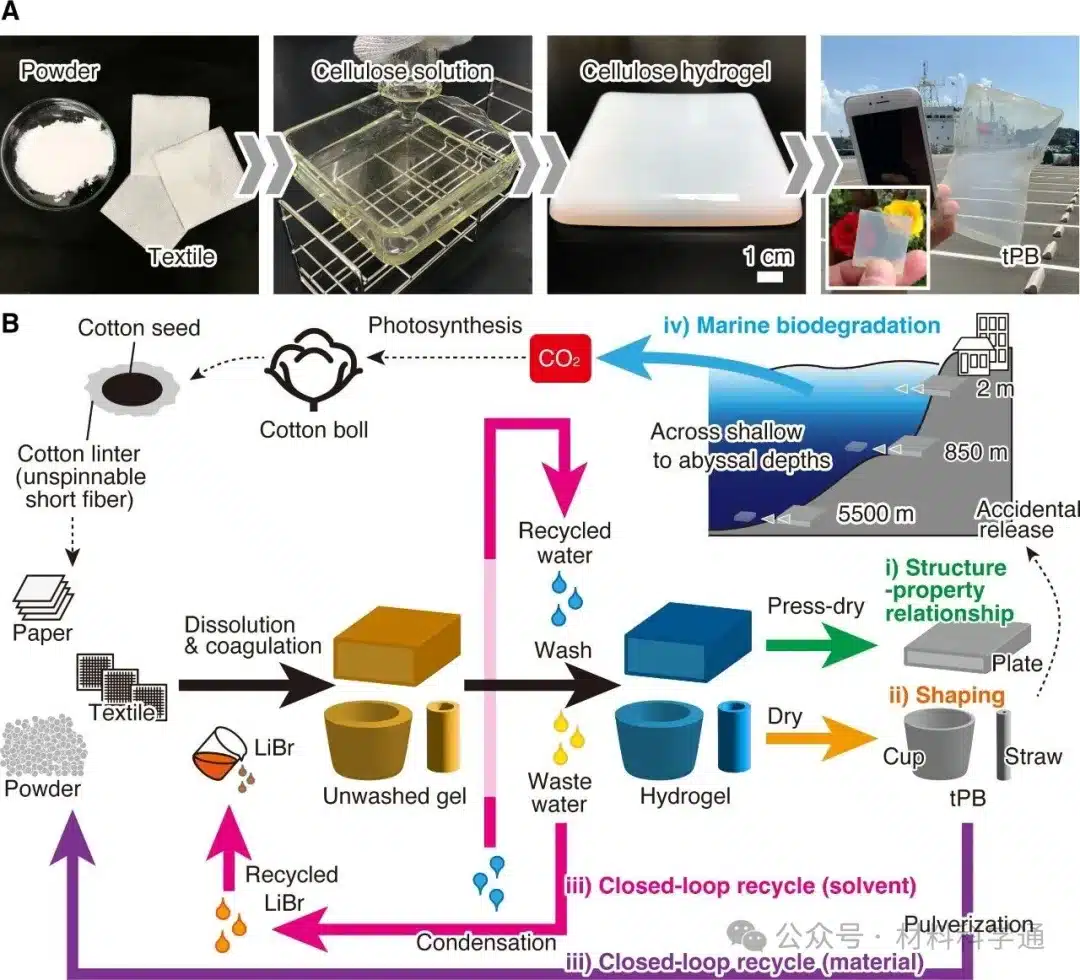

Figure A

From left to right, the images show the transformation of the material:

Powder/Textile → Cellulose solution → Hydrogel → Final product (tPB, transparent poly-biomaterial).

Powder or textile waste is first processed into a cellulose solution;

this solution is then gelled to form a cellulose hydrogel;

finally, it is processed into a transparent bio-based plastic substitute (for example, the transparent cup shown).

Figure B (Process diagram)

Raw materials:

Short cotton fibers (cotton linters, which cannot be spun into yarn) obtained from cotton seeds or cotton bolls, as well as paper or textile waste.

Chemical treatment:

Cellulose is dissolved using the solvent LiBr (lithium bromide) to form a gel.

The gel is then washed to remove the solvent, resulting in a hydrogel.

Recycling:

The LiBr solvent is recovered through condensation (closed-loop recycling), and water is also recycled for reuse.

Materials (such as used transparent cups) can be pulverized and recycled back into powder form.

Shaping and applications:

The hydrogel can be dried, press-dried, or molded into various products such as cups, straws, or transparent sheets.

End of life:

If released into the natural environment (e.g., the ocean), these materials can be biodegraded by microorganisms, preventing long-term accumulation like conventional plastics.

Paper and paperboard come from cellulose in wood. They’re reusable and biodegradable materials alternative to plastic , making them ideal candidates to replace plastics. But there’s a catch: paperboard isn’t transparent, so it can’t replace clear plastics in packaging that needs to show what’s inside (e.g., food boxes, drink cups).

Why is transparency so hard? The culprit is light scattering. The large wood fibers in conventional paperboard scatter light, making it opaque. Until now, the only commercial, cellulose-only transparent film was cellophane, but that process can’t make millimeter-thick boards.

A Japanese team took a different route. They used an aqueous lithium bromide (LiBr) solution. Cellulose dissolves in it when heated and gels again when cooled. By directly drying this thick cellulose hydrogel, the team produced millimeter-thick, smartphone-sized transparent paperboard (tPB), that’s a new alternatives to plastic packaging.

2. Standout Properties: Clear, Tough, and Insulating

High transparency. At 0.7 mm thickness, tPB reaches ~87% total light transmittance with about 22% haze, so distant objects still look clear. Even at 1.5 mm, it remains visibly transparent with only mild fogginess.

Excellent mechanics. It combines the stiffness of paperboard with the flexibility of plastic. In bending tests, it tolerates large deformation without breaking—something normal paperboard can’t do.

Exceptional wet strength. Pure-cellulose materials usually weaken in water. But after being fully immersed for 72 hours, tPB’s tensile strength is still 5–15× that of standard paperboard. It can stand on its own without collapsing.

Natural thermal insulation. Thanks to its anisotropic nanofiber structure, heat flows differently along the plane vs. through the thickness, giving it built-in insulation. In tests with boiling water, the outer wall of a tPB cup stayed noticeably cooler than that of a polystyrene (PS) cup.

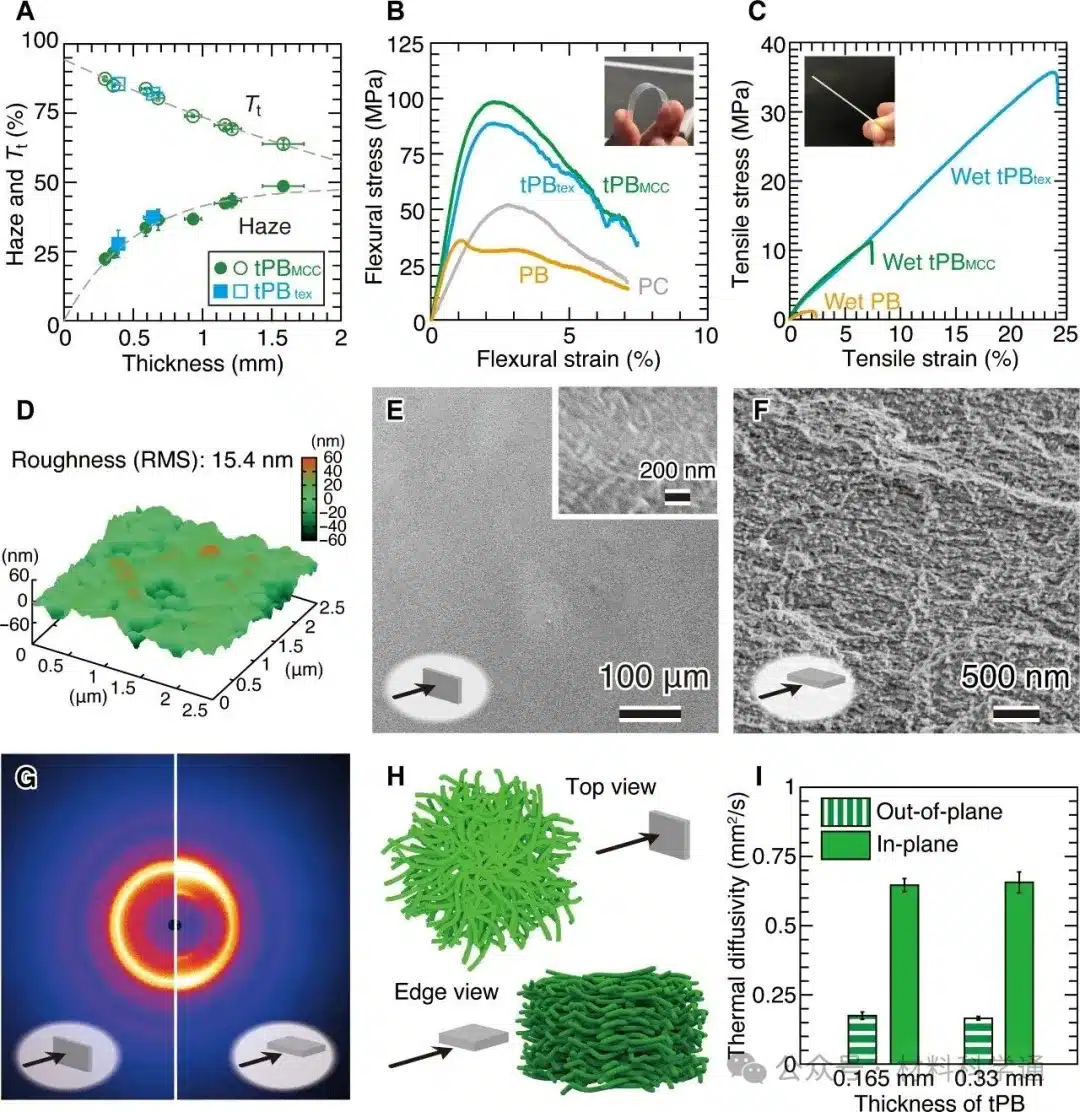

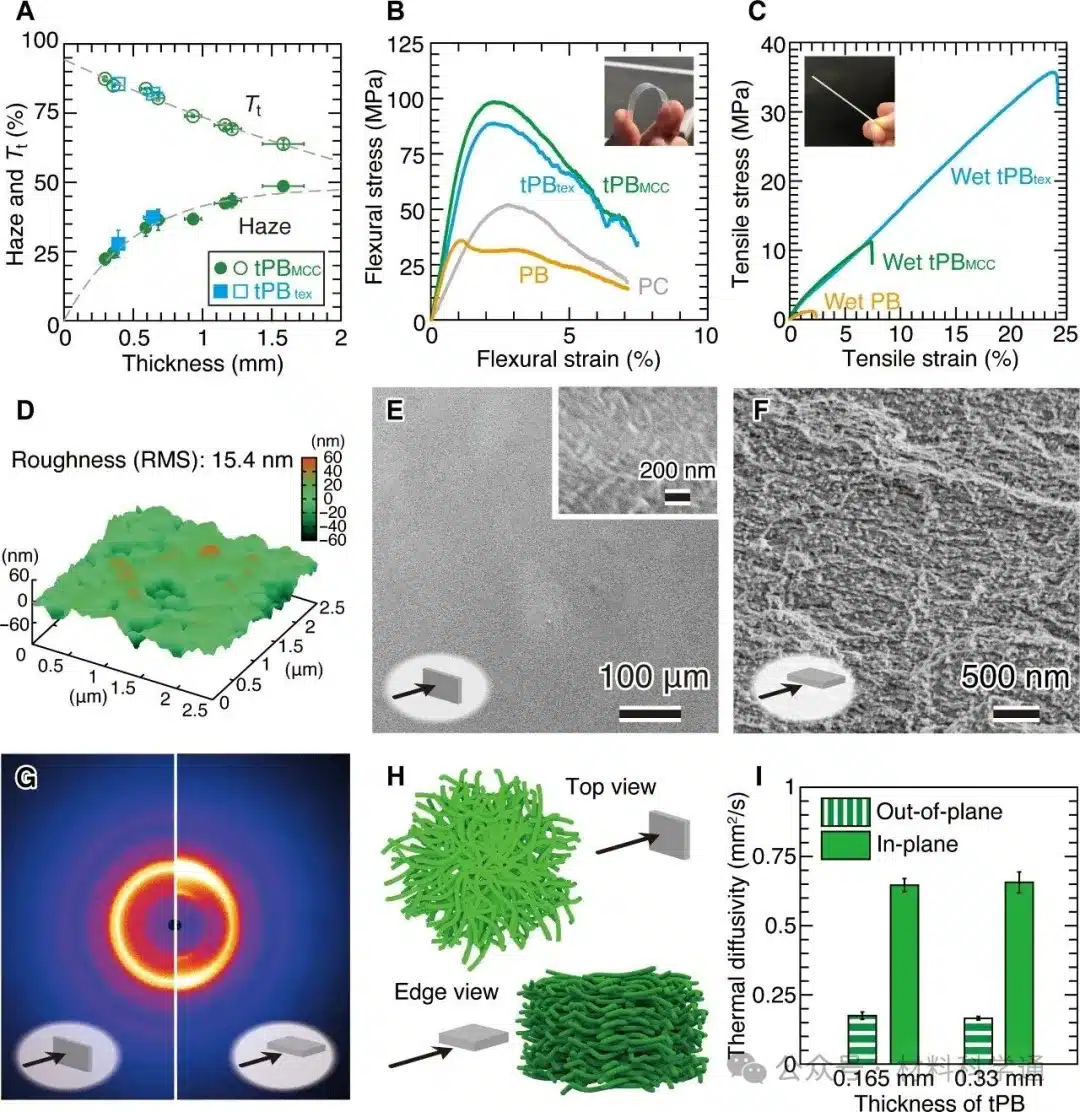

Figure Results – Characterization of tPB (transparent poly-biomaterial)

A. Optical properties

Transmission (Tt) and haze as a function of thickness. tPB maintains high transparency with slightly increased haze as thickness grows.

B. Flexural properties

Flexural stress–strain curves show that tPB (textile-based and MCC-based) exhibits higher flexural strength and toughness compared to conventional PB and PC plastics.

C. Tensile properties

Tensile stress–strain curves indicate that wet tPB still maintains excellent mechanical strength, outperforming traditional PB even in humid or aqueous conditions.

D. Surface roughness

Atomic force microscopy (AFM) shows a root-mean-square roughness (RMS) of ~15.4 nm, demonstrating a smooth surface suitable for optical applications.

E–F. Microstructure

SEM/TEM images reveal a uniform microscale morphology and dense nanoscale cellulose fiber network, which explains the superior mechanical properties.

G. X-ray scattering (SAXS/WAXS)

Ring-shaped diffraction patterns confirm ordered cellulose chain alignment and anisotropy within the structure.

H. Structural model

Schematic diagrams (top view and edge view) illustrate the stacked and oriented cellulose chain network, linking structure to performance.

I. Thermal diffusivity

Thermal transport measurements show anisotropic behavior: in-plane diffusivity is significantly higher than out-of-plane, confirming directional heat conduction.

Summary

Summary: These results confirm that tPB is a transparent, mechanically strong, smooth-surfaced, biodegradable cellulose-based material with ordered nanostructure and anisotropic thermal properties, making it a promising alternative to conventional plastics.

3. Ready to Use Alternatives: Forming Cups and Straws

With these properties, researchers molded tPB into transparent cups and straws.

The game-changer: these cellulose cups can hold hot water without any plastic lining, and without leaking or going mushy. That’s a genuinely eco-friendly alternative to today’s paper-plastic composite cups.

For long-term liquid storage, an ultra-thin plant-based fatty-acid salt coating (about 5–10 μm) on the inner wall is enough—adding durability with minimal impact on sustainability.

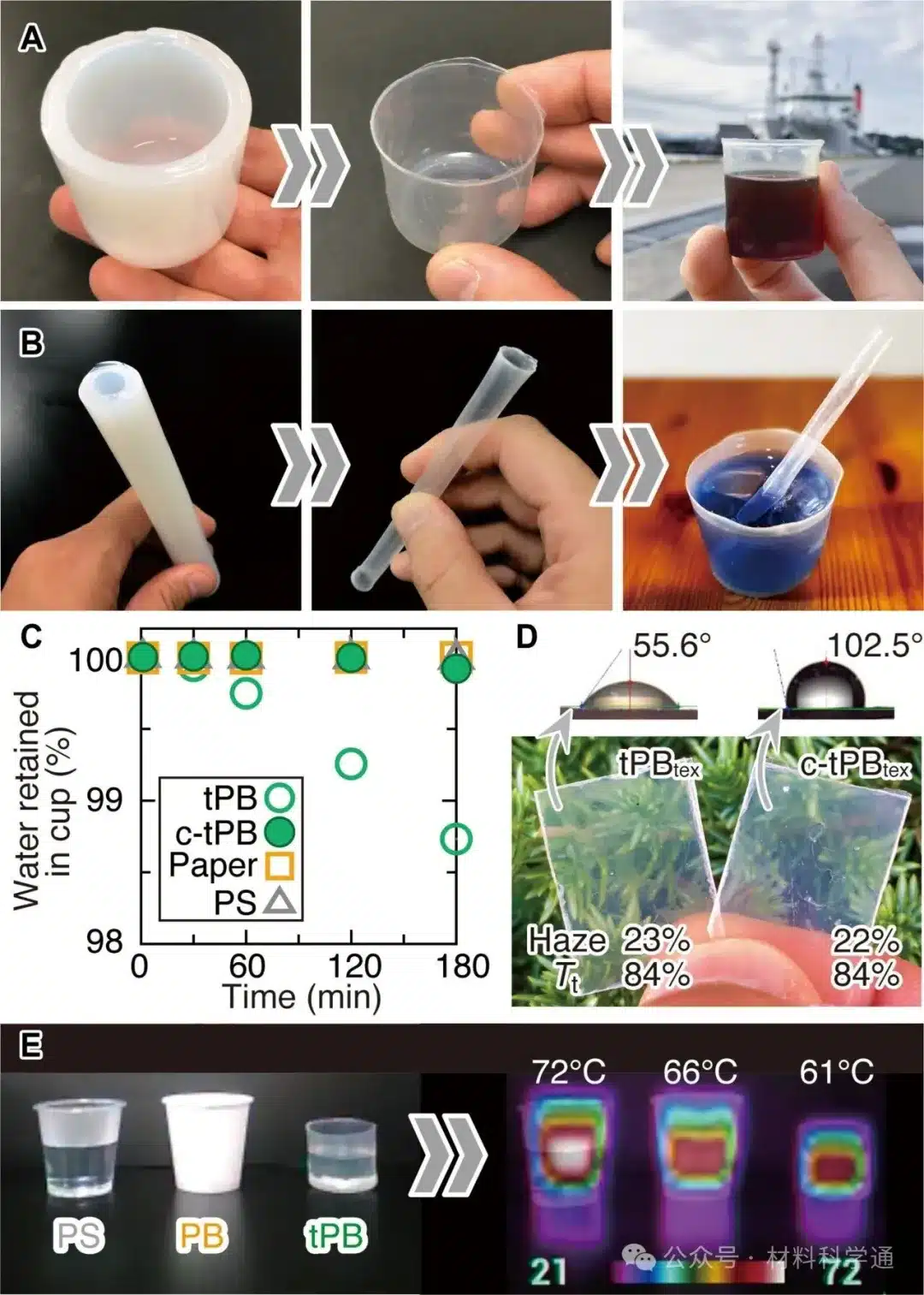

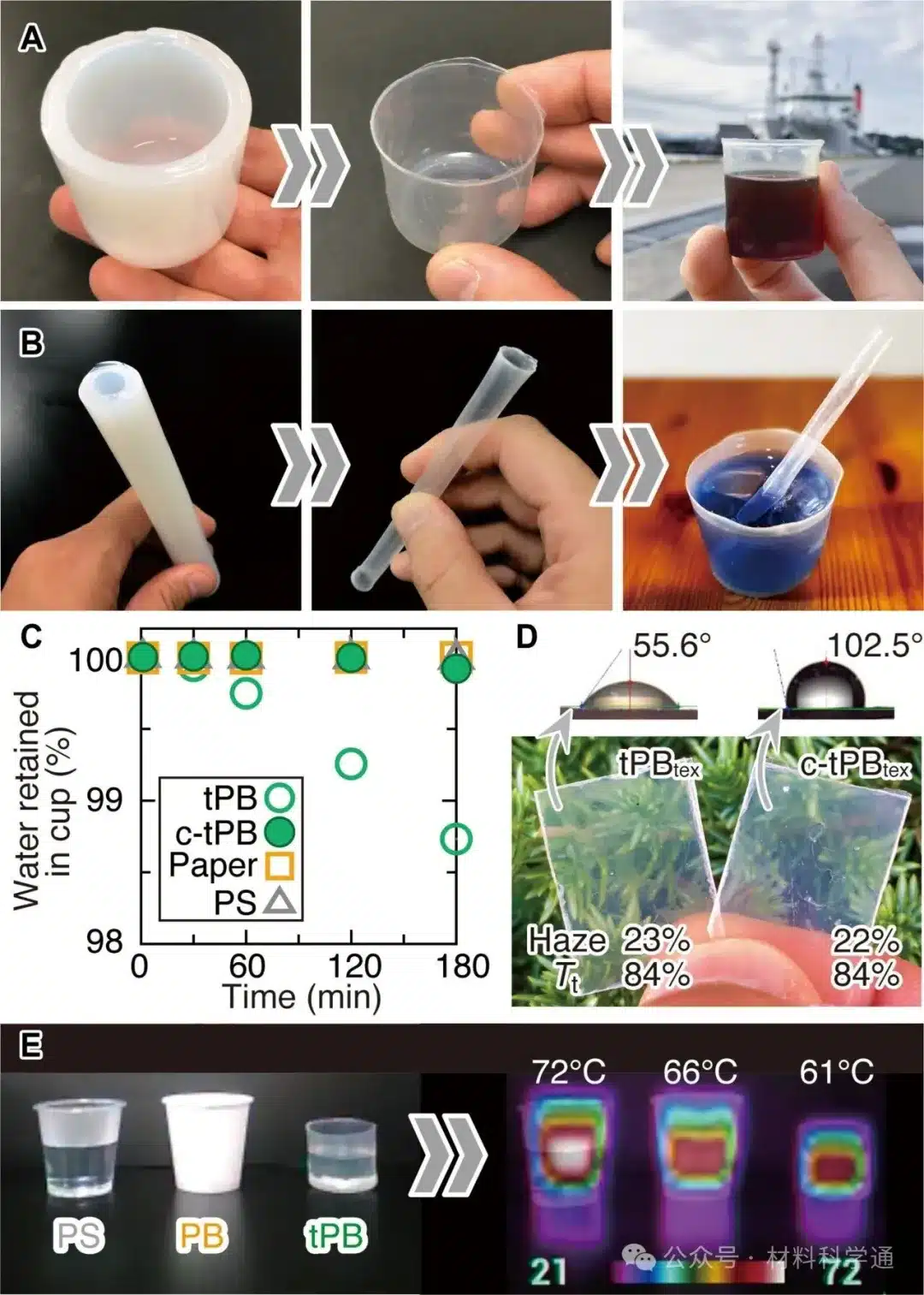

Figure – Functional evaluation of tPB (transparent poly-biomaterial)

A. Cup application:

Wet hydrogel cup dried into a transparent tPB cup, capable of holding liquid effectively.

B. Straw application:

Wet hydrogel straw dried into a transparent tPB straw, demonstrated in actual use for stirring beverages.

C. Water retention performance:

Comparison of water retained in cups over time among tPB, composite tPB (c-tPB), paper, and polystyrene (PS).

Both tPB and c-tPB maintain nearly 100% water retention for extended periods, while paper cups show leakage.

D. Surface wettability and transparency:

Contact angle measurements indicate tPBtex is more hydrophilic (~55.6°) whereas c-tPBtex is hydrophobic (~102.5°).

Both films exhibit low haze (~22–23%) and high transmittance (~84%), confirming good transparency.

E. Thermal insulation:

Thermal imaging of cups containing hot water shows lower external temperature for tPB (~61 °C) compared to PB (~66 °C) and PS (~72 °C), indicating superior heat insulation and safer handling.

Summary

Summary:These results demonstrate that tPB can be fabricated into practical products such as cups and straws, with excellent waterproofing, tunable surface properties, good transparency, and superior thermal insulation compared to conventional plastics.

4. Ultimate Sustainability: Closed-Loop Recycling & Ocean-Wide Biodegradation

Closed-loop recycling. The production process recovers the LiBr solvent and water. Used tPB can be shredded, dissolved, and remade into new tPB. Even after multiple cycles, the regenerated material keeps good transparency and strength—true cradle-to-cradle use.

Biodegrades across the whole ocean. Samples were deployed at four depths, from harbor shallows (~2 m) down to a Pacific trench (~5,552 m). Remarkably, even in cold, high-pressure, low-oxygen deep sea, tPB was biodegraded by microbes at meaningful rates (~20–50 μg/cm²/day). Metagenomic and metatranscriptomic analyses showed biofilms forming on tPB and producing cellulases that break it down into CO₂ and water.

In other words, if tPB ever escapes into the ocean, it won’t become a “permanent deep-sea relic” like many plastics. It returns quietly to nature.

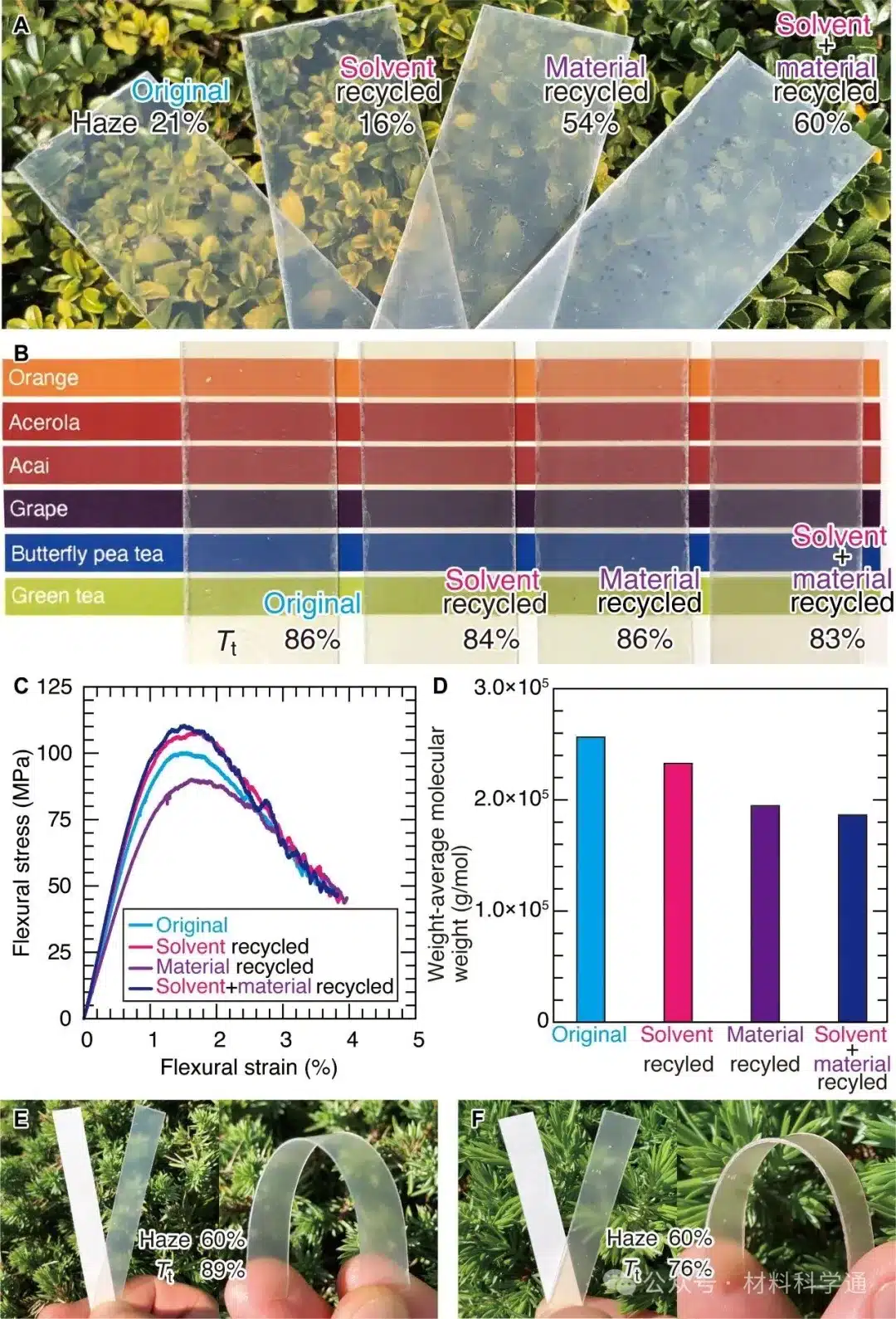

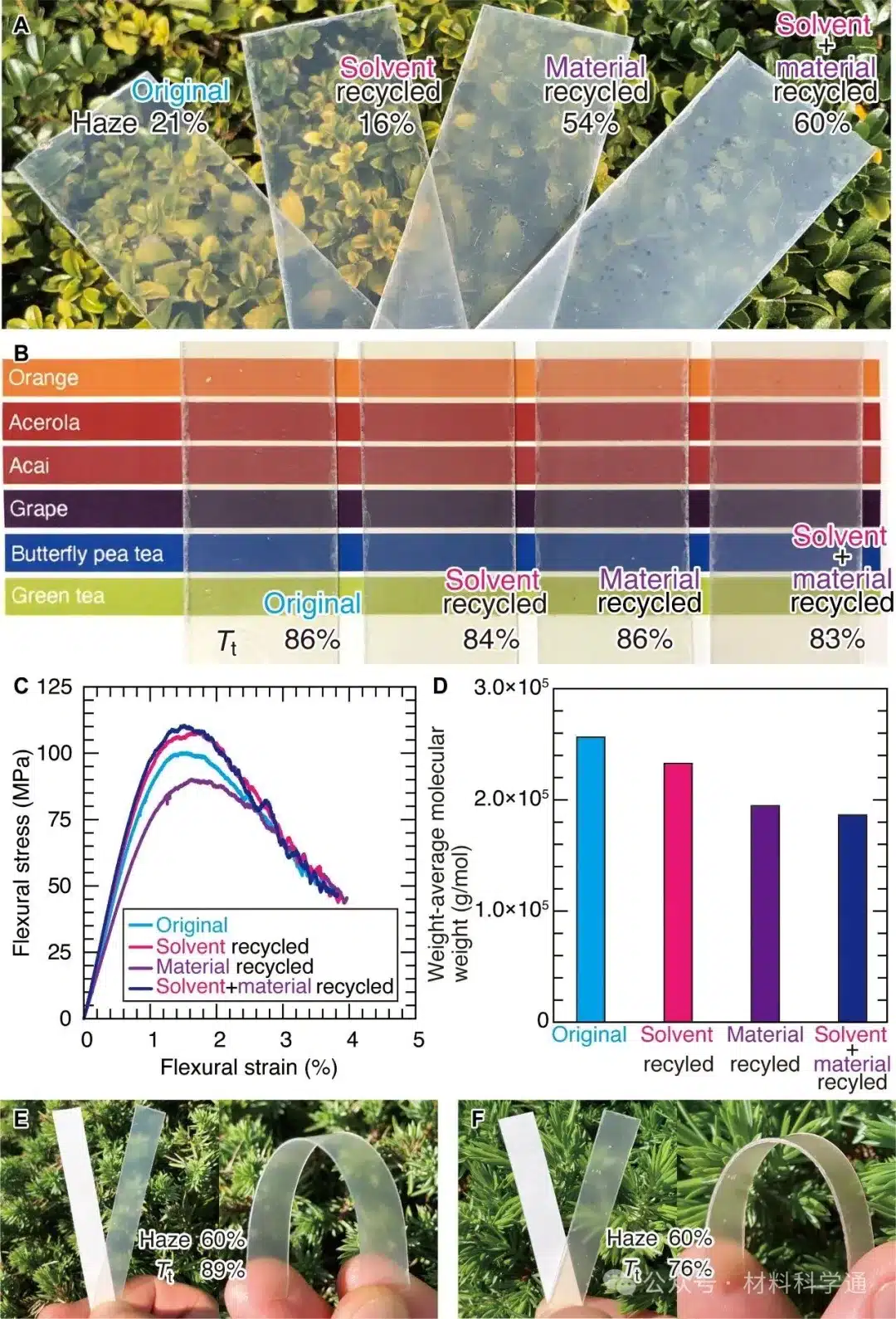

Figure – Recycling performance of tPB (transparent poly-biomaterial)

A. Optical appearance and haze:

Photographs of original, solvent-recycled, material-recycled, and solvent+material-recycled films.

Haze values are 21% (original), 16% (solvent recycled), 54% (material recycled), and 60% (solvent+material recycled).

Solvent recycling preserves transparency, while material recycling increases haze.

B. Transmittance and dye test:

Colored liquids (juices and teas) used as background to evaluate optical clarity.

Transmittance remains high for original (86%) and solvent-recycled (84%) films, while material and solvent+material recycled films show slightly reduced values (~83–86%).

C. Flexural properties:

Flexural stress–strain curves show negligible difference among original and recycled films.

All samples maintain high flexural strength (~100 MPa), indicating mechanical robustness after recycling.

D. Molecular weight analysis:

Weight-average molecular weight (Mw) is maintained in solvent-recycled films but decreases in material and solvent+material recycled films, reflecting partial cellulose chain degradation during recycling.

E–F. Recycled film appearance:

Recycled tPB films still display considerable transparency despite increased haze (60%) and slightly lower transmittance (89% and 76%).

Visual inspection confirms retained usability after multiple recycling routes.

Summary

Summary: These results demonstrate that solvent recycling preserves both optical and mechanical properties of tPB, while material recycling introduces higher haze and molecular weight reduction but still maintains good mechanical performance. This confirms the feasibility of closed-loop recycling for tPB.

5. Looking Ahead: Toward a True Circular Economy

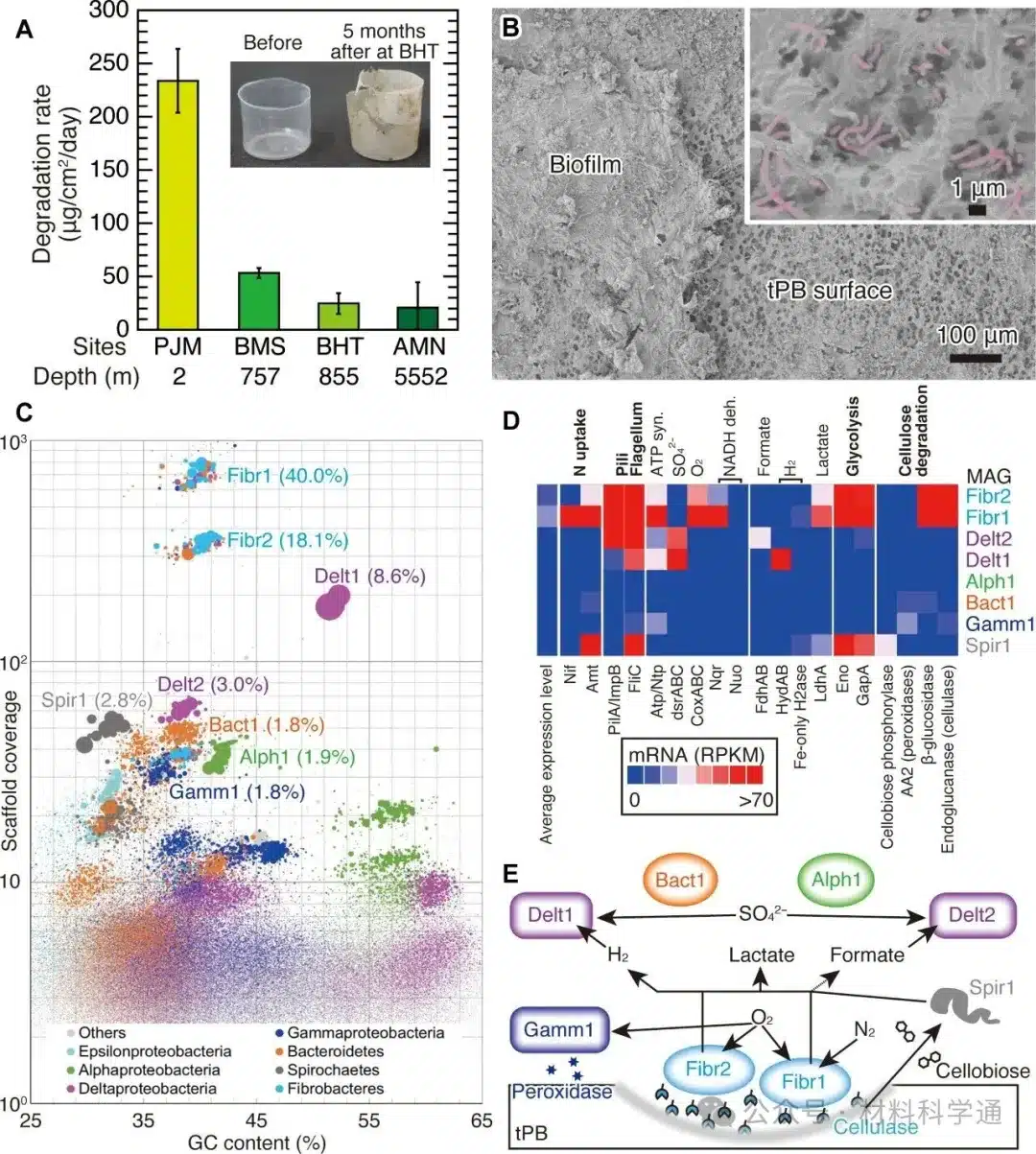

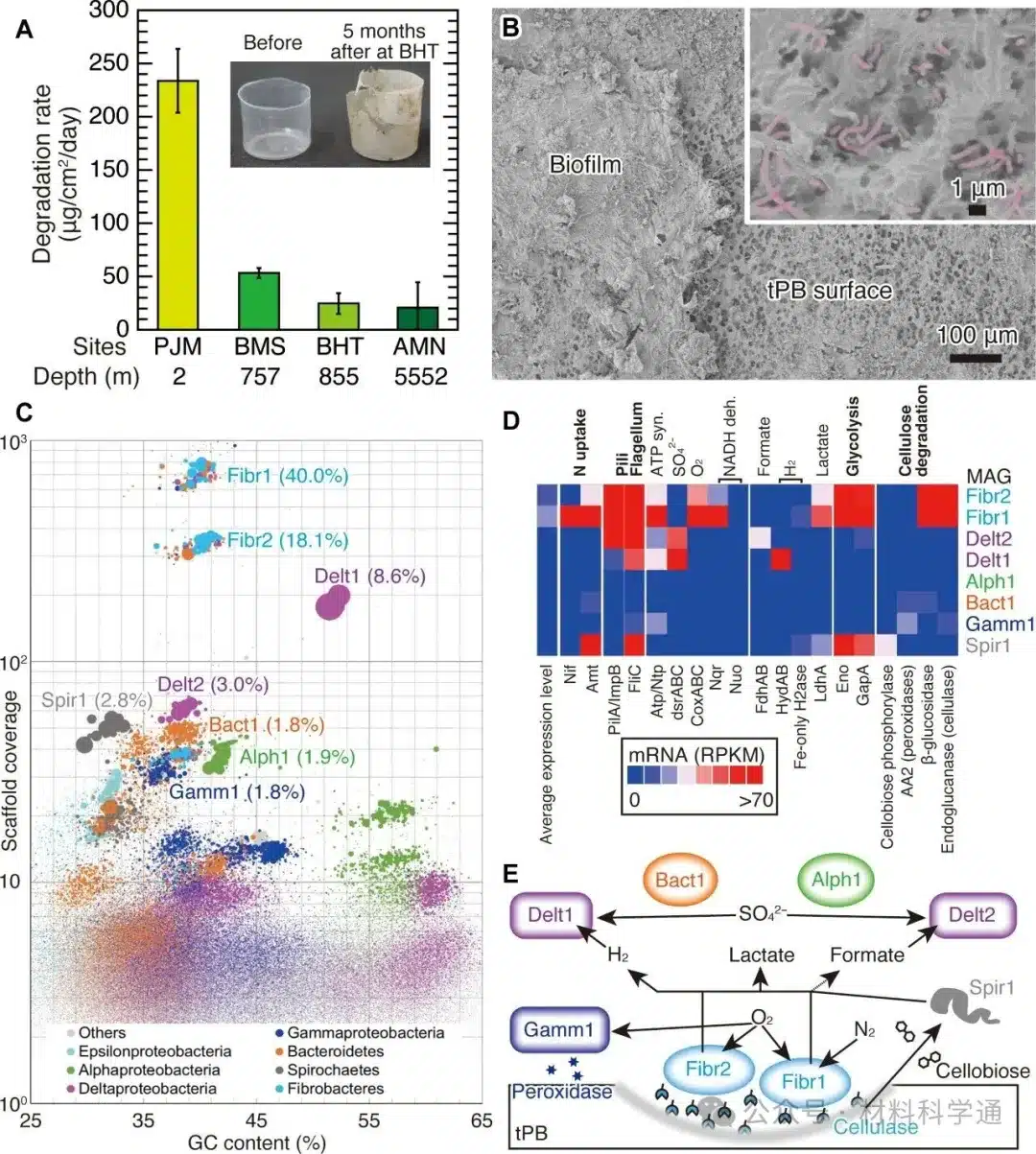

Figure – Marine biodegradation of tPB (transparent poly-biomaterial)

A. Degradation rates at different marine sites:

Degradation measured at PJM (2 m), BMS (757 m), BHT (855 m), and AMN (5552 m).

Shallow waters (PJM) showed the highest rate (~250 μg/cm²/day), while deep-sea sites exhibited slower degradation (~20–50 μg/cm²/day).

Inset: tPB cup before and after 5 months at BHT site.

B. Biofilm formation:

Microscopy images reveal microbial colonization on the tPB surface, forming biofilms.

Magnified view shows attached bacteria, confirming microbial involvement in degradation.

C. Microbial community composition:

Metagenomic analysis identifies dominant groups: Fibr1 (40%), Fibr2 (18.1%), Delt1 (8.6%), Delt2 (3.0%), Spir1 (2.8%), along with Alph1, Bact1, and Gamm1.

Cellulose-degrading bacteria and anaerobes play central roles in the process.

D. Functional gene expression:

Heatmap shows enhanced expression of cellulases, endoglucanases, and β-glucosidases, along with genes related to nitrogen uptake, glycolysis, and fermentation pathways.

Indicates cooperative metabolism within the microbial community during tPB breakdown.

E. Proposed degradation pathway:

Cellulose chains in tPB are hydrolyzed by Fibr1/Fibr2 cellulases into cellobiose.

Delt1 and Delt2 process metabolites into H₂, lactate, and formate, while Alph1, Bact1, Spir1, and Gamm1 contribute to redox balance and auxiliary pathways.

Overall, synergistic microbial activity accelerates marine degradation of tPB.

Summary

These results confirm that tPB is biodegradable in marine environments, with biofilm formation and diverse microbial consortia driving enzymatic and metabolic processes. Degradation occurs faster in shallow waters but is also feasible in deep-sea conditions.

At lab scale, tPB currently uses more energy to produce than conventional paperboard. But the researchers argue that with large-scale, continuous manufacturing—similar to modern paper mills—energy use could drop to levels comparable to regular paperboard.

Born of nature and returning to nature, tPB is an ideal next-generation base material, and it is expected to be widely used to replace plastic packaging. Plastic free, eco-friendly packaging that protects the environment. It could replace many single-use transparent plastic packages that are hard to recycle and prone to leakage into the sea—helping address marine plastic pollution at the root and supporting a truly circular economy.

One day, the transparent coffee cup in your hand may be made from this cellulose board that can “disappear” in the deep ocean.