In today’s world where the environmental wave is sweeping across the globe, pulp molding is leaping from a supporting role in traditional packaging to become a star in the green industry. It not only carries the mission of “replacing plastic with paper,” but also carves out multiple high-potential tracks in niche markets. From food and beverage to daily chemicals and cosmetics, from cultural and creative gifts to electronics and appliances, from medical products to industrial packaging, pulp molding is leveraging “precision customization + environmental DNA” to unlock a hundred-billion-dollar market.

Food and Catering

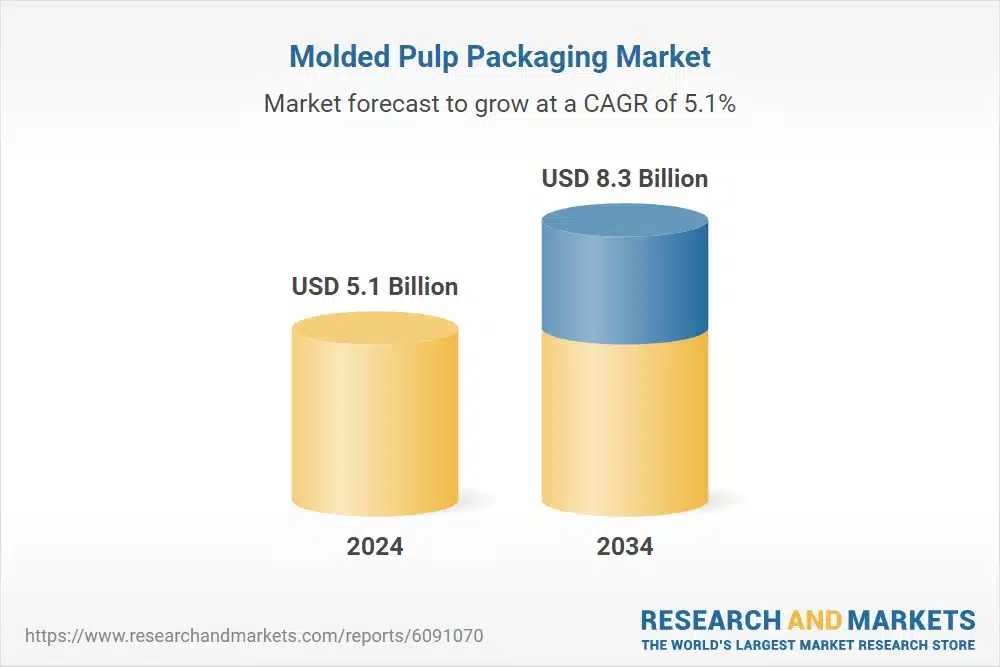

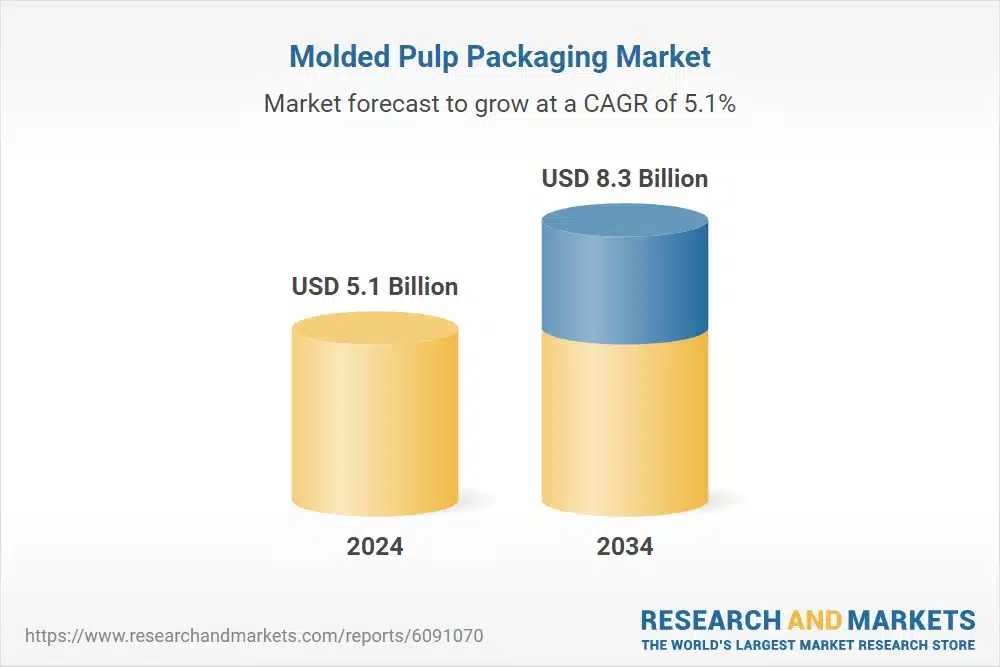

Pulp molding is widely used in the food and catering industry, mainly covering scenarios such as disposable tableware, fresh food trays and baking packaging. According to the data statistics of Grand View Research, the total value of the global pulp molded packaging market reached 5.1 billion US dollars in 2024. In terms of the distribution of application fields, the packaging of the food and beverage industry takes up a large share, with a value of 2.9 billion US dollars, accounting for approximately 56.9% of the entire market. Among product types, molded pulp pallets have become a dominant area, generating $1.9 billion in revenue in 2024. According to the prediction of Grand View Research, the industry is expected to grow at a compound annual growth rate of 4.9% by 2034. Among them, driven by the protective characteristics and environmental appeal of pallets, the segment market of molded pulp pallets is expected to grow at a compound annual growth rate of 5.2%.

Forty percent of Starbucks’ stores worldwide have adopted sugarcane pulp cup LIDS, with an annual consumption of over 3.5 billion. In 2024, McDonald’s China purchased over 2 billion pulp molded lunch boxes, accounting for 58% of its total packaging volume. The leak-proof pulp molded lunch boxes for Haidilao hot pot takeout adopt a patented water-locking structure, and the sealing performance of the soup has passed the FDA 21CFR test. According to data from the International Air Transport Association (IATA), global airlines purchased 4.3 billion pulp molded lunch boxes in 2023.

Daily Chemical and Beauty Products

In the field of daily chemical and beauty products, pulp molding is often used for cosmetic packaging boxes and packaging of toiletries. Like the packaging boxes of some high-end lipsticks, they adopt pulp molding combined with exquisite printing techniques to create a beautiful and environmentally friendly product appearance. Some brands of shampoo and body wash sets use pulp molding as the inner lining, which serves to fix and protect, enhancing the product grade. According to data from Euromonitor International, the global market size of pulp molded packaging in the beauty industry reached 2.8 billion US dollars in 2023, with an annual growth rate as high as 24.3%.

Nu Silk skin care product packaging

In terms of material selection, the packaging design of Nu Silk adopts sustainable pulp molding. This material not only has a natural appearance but is also very environmentally friendly. Its packaging box can be 100% biodegradable. The designer retained the original touch of the pulp to convey the concept of pure ingredients in the product.

HalfMagic eyeshadow palette

This potato starch-based compostable makeup palette, with its rough granular texture and matte eyeshadow creating a visual unity, has won Dieline’s “Plastic-Free Innovation of the Year Award”. Paper Foam, as a low-carbon and environmentally friendly packaging material, not only reduces carbon emissions during the production process, but also can degrade rapidly after being discarded, effectively reducing pollution to the environment.

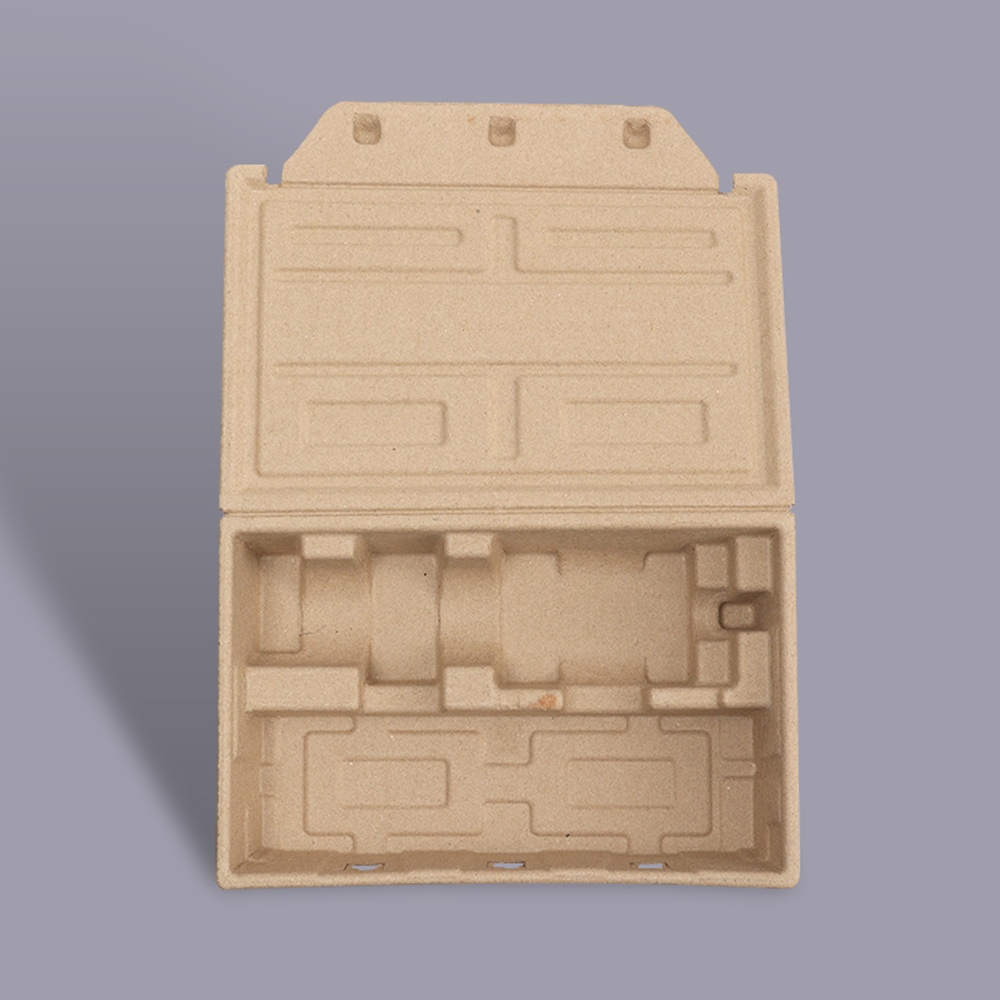

When NOS designed the packaging of the everloop toothbrush, it adopted hot-pressing molding technology for one-piece molding. The packaging box features an open lid design, which is convenient for users to open and close. This design not only makes it convenient for users to take the toothbrush, but also keeps the box clean and beautiful. Meanwhile, the pulp molded packaging of everloop toothbrushes is also designed with grooves and clips to ensure that the toothbrushes can be stably placed in the box and prevent damage during transportation or storage.

Cultural and Creative Products

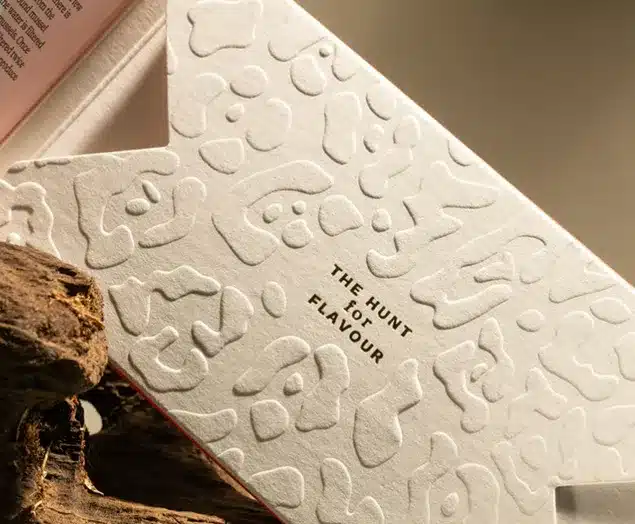

In terms of cultural and creative gifts, pulp molding can be made into uniquely shaped gift boxes, stationery storage boxes, artistic ornaments, etc. By designing an exquisite pulp molded structure and integrating traditional cultural elements, it not only protects the gift but also has ornamental and collection value. There are also creative pulp molded pen holders, business card boxes and other stationery items, which are both practical and artistic.

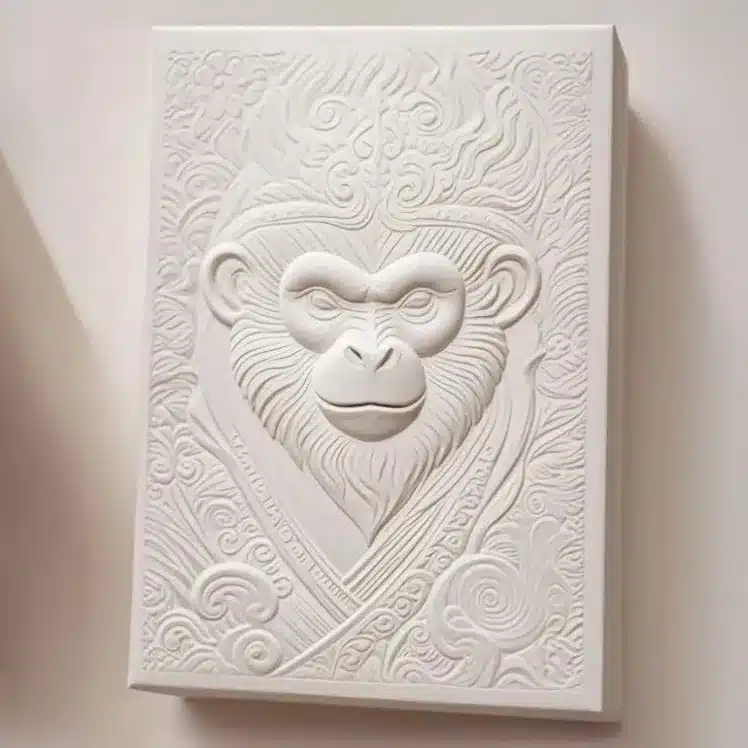

Black Sun Wukong paper model three-dimensional relief box

The ecological Tiankongzi brand Dongzhisu has launched the first “Wukong Battle Armor Paper Mold” using the fine three-dimensional relief pulp molding process, successfully transforming this iconic cultural symbol into a tangible cultural tree ring, providing a vast space for imagination in the packaging of cultural and creative gifts.

This process breaks through the physical limit of the pulp molding process, adopts a engraving accuracy of 0.02mm, and pioneers the “fiber directional layering” technology, making the relief effect more prominent. Not only was the hair fine and visible, but even the wear and tear on the gold band between the forehead could be clearly felt. This product is free of chemical adhesives throughout the process. It achieves 3D support solely through a fiber self-locking structure, yet its load-bearing strength rivals that of solid wood carvings, allowing environmental protection and art to coexist perfectly.

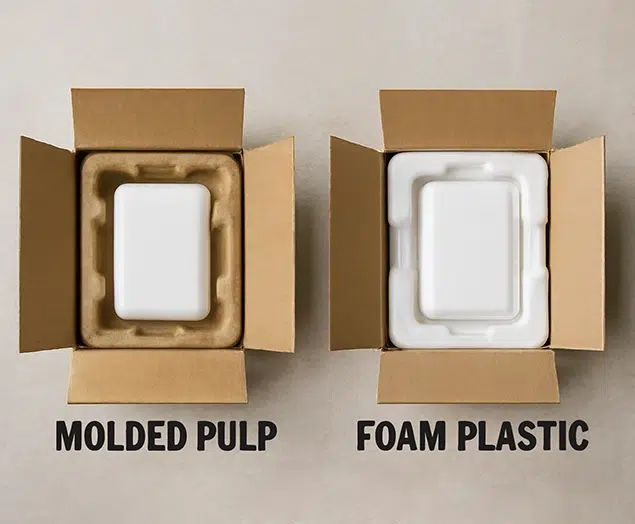

Electronics and Electrical Appliances

In the electronics and electrical appliances industry, pulp molding is mainly used for cushioning packaging of products. For instance, in the packaging boxes of electronic products such as mobile phones, tablet computers and televisions, pulp molded inner linings are often used, which can effectively absorb and disperse the impact force during transportation, protecting the products from damage. According to the IDC report, the global market size of pulp molded packaging in the electronics and electrical industry reached 4.2 billion US dollars in 2023, with a year-on-year growth of 28.5%. It is expected to exceed 8.5 billion US dollars by 2026, with a compound annual growth rate of 26.3%.

The moto Razr50d has launched a custom packaging made of bamboo fiber

At the CES exhibition in 2025, the moto Razr50d launched a custom packaging made of bamboo fiber, integrating the natural fragrance formulated by Firmenich. The unboxing experience combines a sense of technology and ceremony. The packaging box adopts a self-locking bottom structure, completely eliminating plastic tape and achieving “zero plastic from the inside out”.

Lenovo notebook packaging

Lenovo launched the “Plastic Cushioning Replacement Plan” in 2022 and aims to achieve 100% coverage of pulp molded packaging by 2024. Flagship models such as the ThinkPad X1 Carbon adopt a composite molding material of bagasse and bamboo fiber, reducing the weight by 30% and lowering carbon emissions by 50%.

Beats x Kim co-branded headphones packaging

Beats headphones continue to adopt all-pulp molded packaging in its new product “Beats x Kim”. This packaging method not only helps to reduce carbon emissions, but also meets the environmental protection requirements of the European Union and the United States. Pulp molded packaging is made from renewable resources, has a relatively small impact on the ecosystem, and also has the advantages of strong protective performance, easy stacking and carrying.

Healthcare Products

In the healthcare field, pulp molding, with its characteristics such as environmental friendliness, safety and customization, is becoming an important choice for packaging and supplies in the industry. According to data from Grand View Research, the global market size of pulp molded packaging in the healthcare field reached 1.98 billion US dollars in 2023 and is expected to exceed 3.2 billion US dollars in 2026. The compound annual growth rate is 17.4%.

German Papacks uses waste paper pulp and straw fibers to make paper medicine can, which are lightweight, shock-absorbing, moisture-proof and oxygen-proof. Sensitive medicines are coated with plant-based materials and can be directly chopped and recycled after use, reducing transportation carbon emissions by 70% compared to plastic medicine can.

Tongshen Bio-Health Collagen Drink

The outer box of Tongshen Bio-Health Collagen Drink is made of high-end wet-pressed paper mold as the base material, which is environmentally friendly and degradable. Combined with the one-piece embossed process, it is simple yet elegant. The inner bottle is presented in a transparent and scalded form, expressing a sense of sweetness and coolness as well as quality. It is sharp yet gentle, conveying the independent and soft personality of a new and innovative woman. The touch has enhanced the social attribute, providing a more comfortable experience for beauty care.

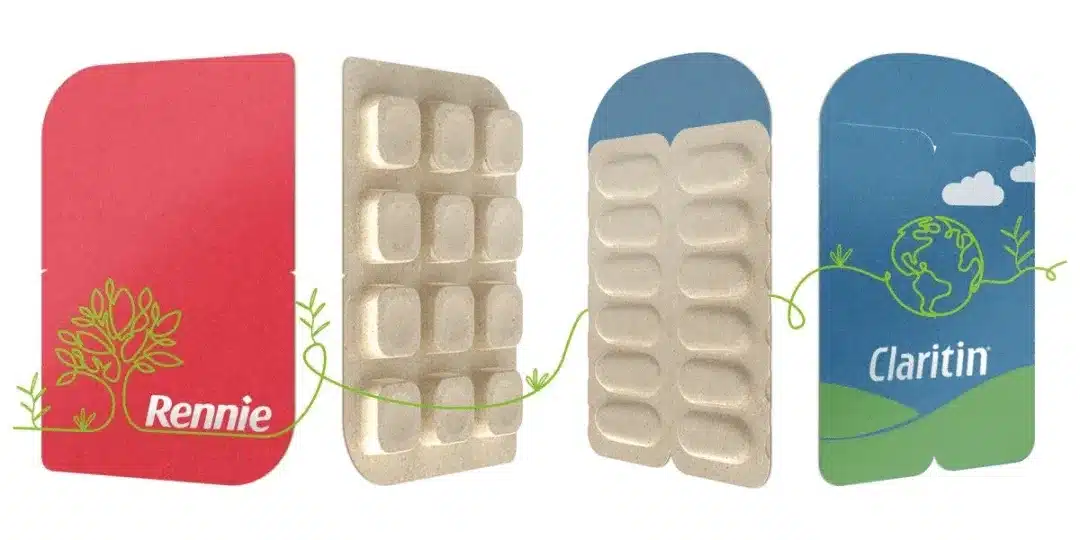

Bayer’s new type of tablet medicine pulp molded packaging

The international pharmaceutical giant Bayer has joined the Blister Pack Collective established by PA and PulPac. Bayer will manufacture new tablet drug pulp molded packaging with the help of PulPac’s dry molding fiber technology, namely pulp molding dry pressing technology. Dry mold fiber technology generates 80% less carbon dioxide footprint and uses less water than the production of plastic packaging. The new type of pulp molded packaging produced by this technology can be comparable to plastic packaging in terms of functionality, design and the number of tablets, and at least 100,000 tons of plastic pharmaceutical packaging can be reduced every year.

Industrial Packaging

In industrial packaging, pulp molding can be used for packaging fragile items such as mechanical parts, ceramic products, and glass products. By customizing pulp molded packaging according to the shape of the product, it provides all-round protection for the product and avoids damage during transportation and handling. For some components of large industrial equipment, pulp molding can also be used for packaging to reduce packaging costs and environmental pollution. Tesla uses bamboo pulp molded tray to transport battery packs, which improves impact resistance by 30% and reduces logistics costs through lightweight design.

From convenient takeout boxes for food and catering to sterile packaging for medical and health care; From the shock-resistant inner lining of electronic and electrical appliances to the solid support of industrial equipment, pulp molding is knocking on the doors of all walks of life with “environmental protection genes” as its base color and “precise customization”. Driven by both policy regulations and consumption concepts, it is not only a green choice for enterprises to fulfill their social responsibilities, but also a differentiating tool for shaping brand competitiveness.

As technological breakthroughs continue to reduce costs and expand performance boundaries, the application scenarios of pulp molding will keep extending. The potential of this blue ocean market worth hundreds of billions of yuan is far from reaching its ceiling. In the future, it will continue to lead the green transformation of the packaging industry, turning sustainable development from a concept into reality and writing more possibilities for the win-win situation of the Earth’s ecology and commercial value.