In the black liquor pools of paper mills, crop stubble in fields, and wood processing scraps lies a long-ignored “green goldmine”: lignin. This natural polymer, second only to cellulose in global abundance, produces over 50 million tons annually worldwide. Yet due to its complex structure and separation challenges, it was once considered industrial waste for burning or landfilling.

However, with technological breakthroughs, lignin is transforming from “waste” to “treasure,” expanding from traditional industries into biomedicine, new energy, and even pandemic response. From the dusty fields of agricultural waste to the cutting-edge laboratories developing virus-fighting materials, lignin represents humanity’s most promising pathway toward a sustainable bioeconomy.

Industrial Materials: Reshaping Manufacturing

Polymer Revolution

Lignin’s rich phenolic hydroxyl groups and aromatic ring structures make it a green alternative to petroleum-based materials:

Engineering plastics replace 60% of phenol in phenolic resin production, maintaining over 90% flexural strength while reducing VOC emissions by 50%. Rubber reinforcement agents substitute carbon black to boost natural rubber tensile strength to 18 MPa, improving wear resistance by 30%.

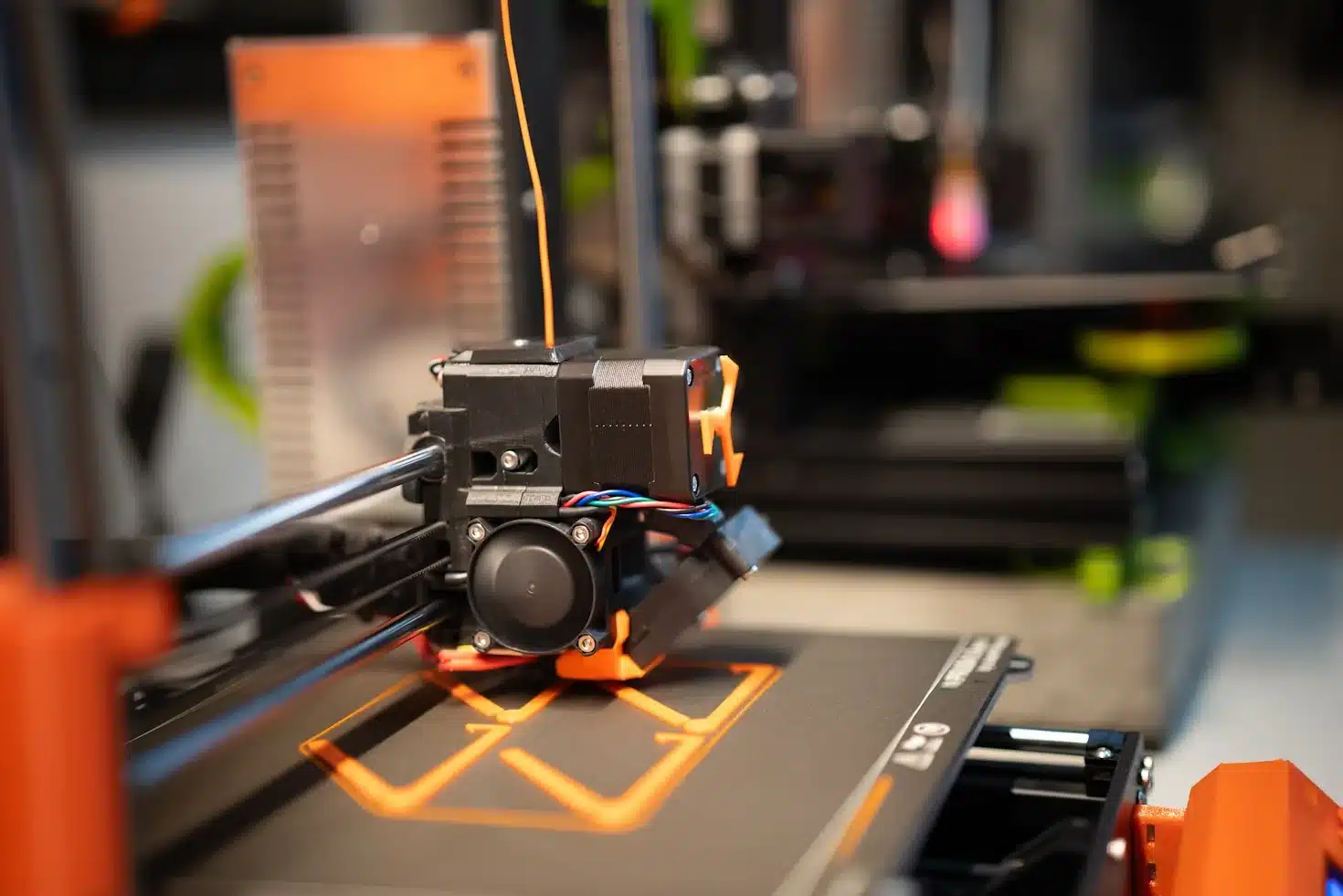

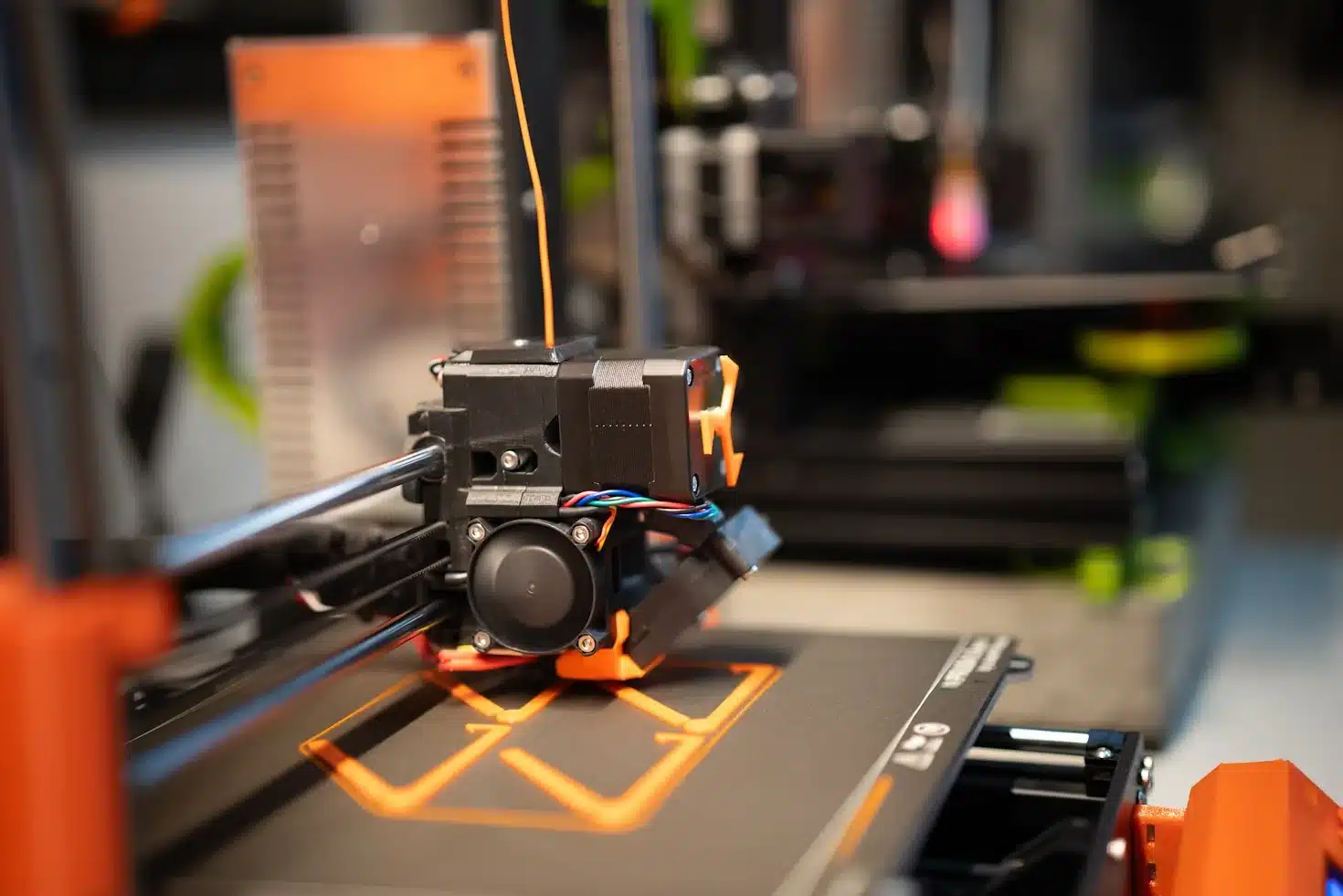

Advanced 3D Printing Technology

3D printing materials blend with PLA to create fully bio-based printing filaments that achieve 80% soil degradation in 6 months.

Carbon Material Precursor

Lignin pyrolysis converts into high-end carbon materials:

Low-cost carbon fiber achieves tensile strength exceeding 1.2 GPa at 40% lower production costs than polyacrylonitrile-based carbon fiber. Supercapacitor electrodes from porous carbon materials reach 250 F/g specific capacitance with over 5,000 charge-discharge cycles.

Advanced Automotive Materials

Lithium battery anodes deliver over 80% first-cycle efficiency and 350 mAh/g capacity.

Energy and Environment: Driving Green Transformation

Clean Energy Carrier

Lignin’s high heating value (26 MJ/kg) characteristics are being deeply developed:

Solid fuel pellets replace coal, reducing sulfur emissions during combustion by 70%. Bio-aviation fuel feedstock through catalytic pyrolysis produces oil with octane ratings over 90, already tested in aviation fuels.

Industrial Biomass Processing

Green hydrogen source via supercritical water gasification achieves 99% hydrogen purity, supporting zero-carbon energy.

Environmental Remediation Tool

Heavy metal adsorbent materials, when modified, achieve 300 mg/g adsorption capacity for lead and copper ions at one-fifth the cost of activated carbon. Soil remediation agents promote microbial degradation of polycyclic aromatic hydrocarbons, improving contaminated soil remediation efficiency by 40%.

Biomedicine: New Guardian of Life and Health

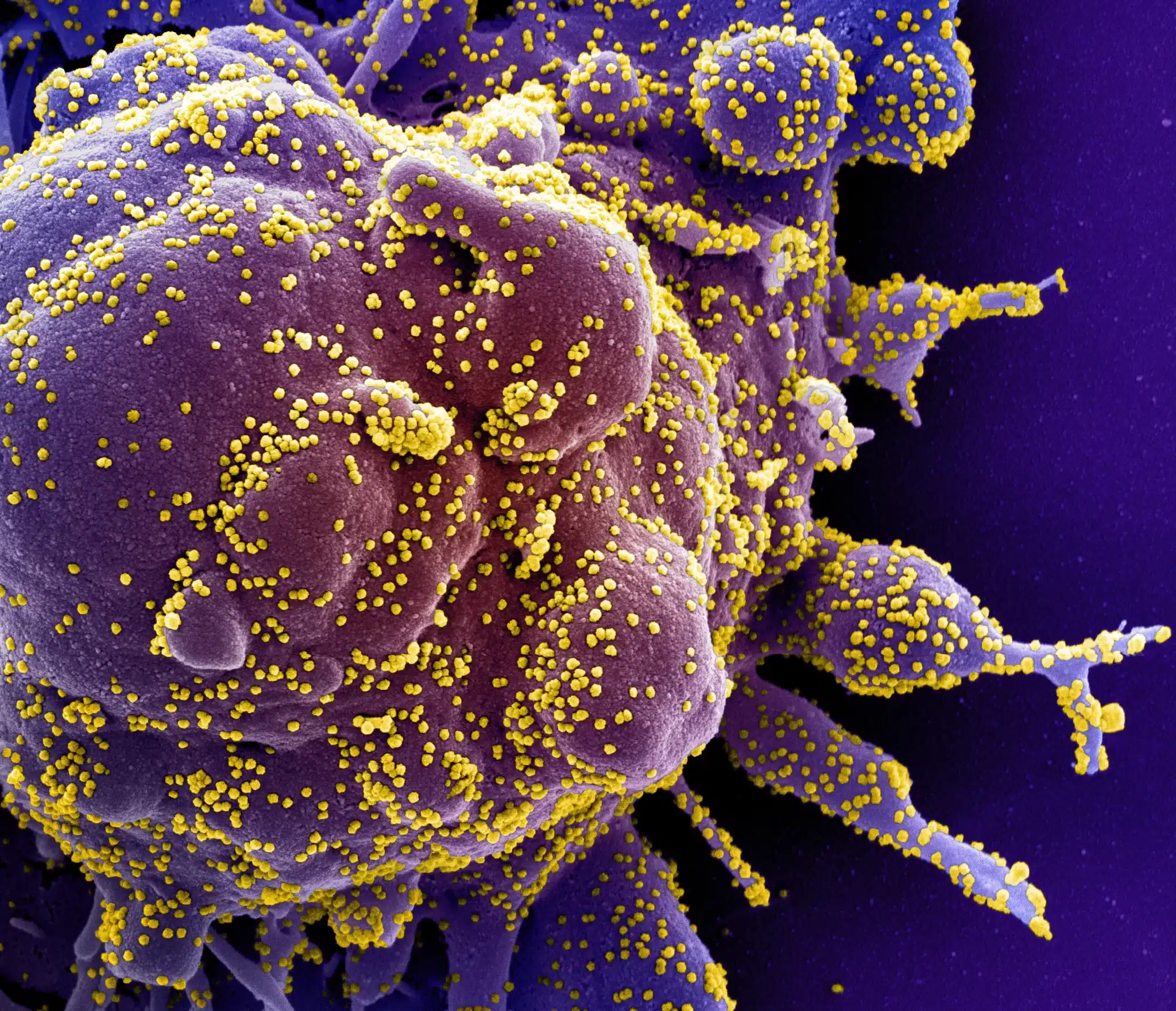

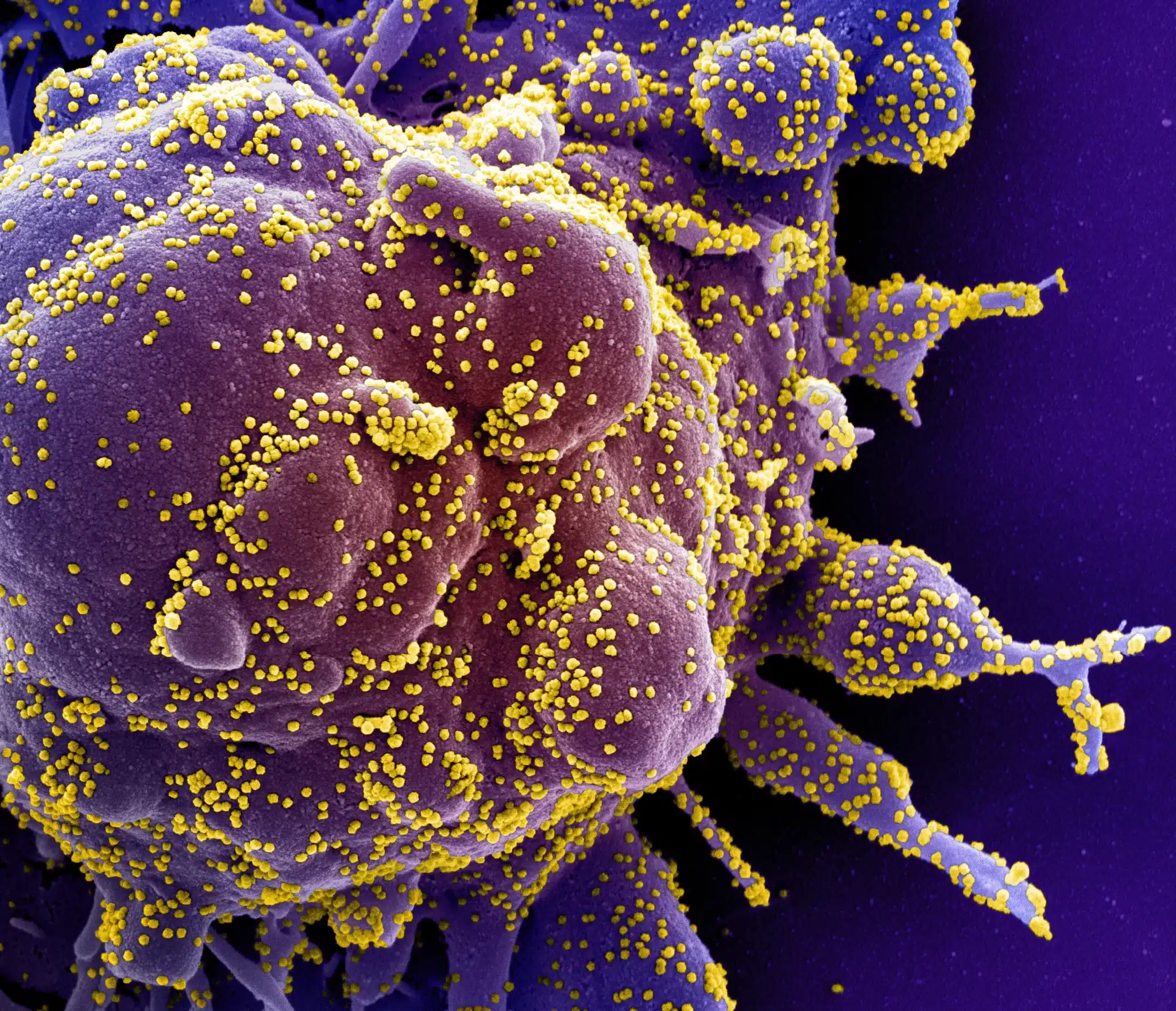

Pandemic Breakthrough

2025 Finnish research revealed lignin’s broad-spectrum antiviral and antibacterial capabilities:

Significant inhibitory effects on both non-envelope enteroviruses (like poliovirus) and envelope viruses. Works by stabilizing viral structures and blocking intracellular replication, creating inhibition zones over 15mm diameter against Staphylococcus aureus and E. coli.

SARS-CoV-2 Coronavirus Structure

Precision Medical Applications

Targeted drug carriers using nanoparticles encapsulate anti-tumor drugs for 72-hour sustained release. Tissue engineering scaffolds with 95% porosity 3D structures maintain over 90% cell viability. Wound dressings made from quaternized lignin achieve over 99% antibacterial rates and accelerate wound healing.

Raw Biomass Materials

Agriculture and Food: From Soil to Table

Smart Agriculture

Slow-release fertilizers using lignin-coated urea boost nitrogen fertilizer utilization from 35% to 70%. Disease resistance inducers activate crop systemic resistance, reducing pesticide use by 30%.

Agricultural Biomass Resources

Food Innovation

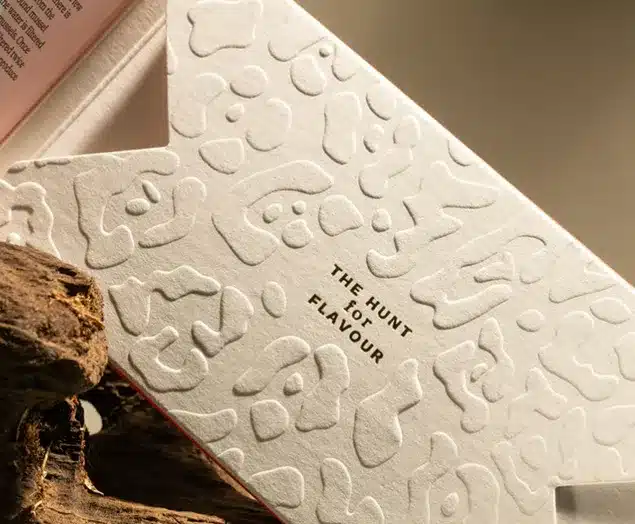

Natural antioxidants contain 5.2 mmol TE/g polyphenols, superior to green tea extracts. Edible packaging films made from antibacterial lignin-chitosan composites extend fruit and vegetable shelf life by 50%. Emulsification stabilizers create O/W emulsions with 85% stability index, replacing synthetic emulsifiers.

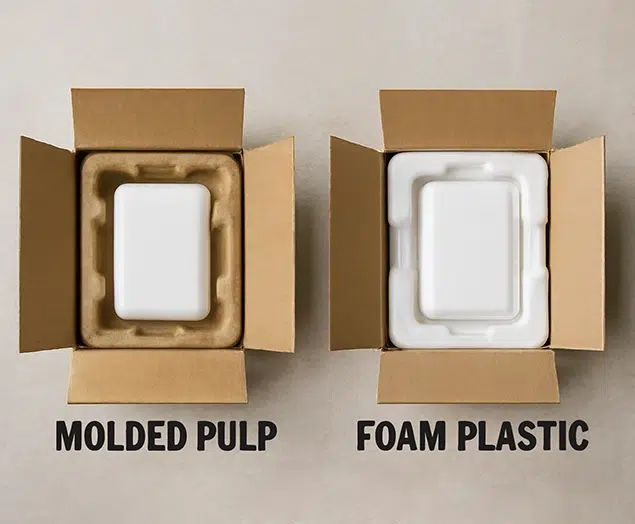

Sustainable Packaging Solutions

Emerging Frontiers: Defining Future Materials

Electronic Devices

Flexible batteries using lignin-polypyrrole conductive materials maintain performance after 10,000 bending cycles. Biosensors with carbon quantum dots achieve 35% fluorescence yield for pathogen detection.

Green Chemistry

Vanillin synthesis through oxidative degradation produces natural-grade vanillin priced three times higher than synthetic versions. Bio-based phenol from catalytic pyrolysis products reaches 99.5% purity, replacing petrochemical feedstock.

Natural UV Protection Applications

Daily Chemical Applications

Sunscreen components using lignin nanoparticles achieve UPF 50+ UV shielding. Skincare additives with antioxidant properties delay skin photoaging.

Challenges and Future: The Trillion-Dollar Market Waiting

Despite broad application prospects, lignin industrialization faces three major challenges:

Structural heterogeneity varies molecular weight by up to 10 times across different plant sources, affecting product stability.

High separation costs account for over 60% of end-product costs, with ionic liquid recovery rates needing improvement.

Missing standards lack unified international standards for lignin classification and application compatibility.

Breakthrough Directions Already Here:

Finnish water-based extraction technology achieves high-purity extraction from birch shavings, driving antibacterial packaging industrialization. Enzyme-DES synergistic processes from Denmark achieve 91% lignin recovery with 70% reduced enzyme usage. Lignin anode materials developed by Japan Paper Industries with Northvolt improve lithium battery energy density by 15%.

The Awakening Era of Green Gold

From the “industrial burden” of burning and landfilling to the “universal material” spanning over 30 fields, lignin’s transformation proves the power of green technology. When every stalk, every wood chip becomes a carrier of the bioeconomy, when every gram of lignin replaces petroleum-based products, humanity’s transition to a sustainable future gains solid footing.

Every strand of lignin gifted by nature carries life’s precisely written code. When humans learn to decode this green genetic blueprint, even waste piles will rise to become seas of stars.

For manufacturers seeking sustainable alternatives to traditional materials, lignin-based solutions offer compelling advantages. Whether for industrial packaging applications or consumer products requiring natural antimicrobial properties, this biomass transformation represents more than environmental responsibility–it delivers measurable performance improvements while reducing costs and meeting consumer expectations for sustainable innovation.

| Application Category |

Representative Technology |

Technology Maturity |

Market Potential |

| Energy & Environment |

Biofuels/Adsorbents |

★★★★☆ |

Hundreds of billions |

| Polymer Materials |

Plastic modification/Carbon fiber |

★★★☆☆ |

Trillions |

| Biomedicine |

Drug carriers/Antimicrobial materials |

★★★☆☆ |

Tens of billions |

| Agriculture & Food |

Slow-release fertilizers/Functional packaging |

★★★★☆ |

Five hundred billions |

| Electronics & Advanced Materials |

Battery anodes/Quantum dots |

★★☆☆☆ |

Emerging markets |

Main Lignin Applications and Technology Maturity Assessment